Top Electric Wire Types to Consider for Your Next Project in 2025

As we approach 2025, the landscape of electrical wiring continues to evolve, driven by advancements in technology and increasing demand for energy efficiency. According to the latest report from the International Energy Agency (IEA), the global electricity demand is expected to rise by 30% over the next decade, highlighting the urgent need for reliable and efficient electric wire solutions. Electric wires play a crucial role in the infrastructure of residential, commercial, and industrial projects, and selecting the appropriate type is essential for optimizing performance and safety.

The ongoing shift towards renewable energy sources and the rise of smart home technologies are fueling the development of specialized electric wire types that are better suited for these applications. For instance, data from the National Electrical Manufacturers Association (NEMA) indicates that the market for low-voltage wires has grown significantly, as more projects incorporate automation and energy management systems. This evolution necessitates a deep understanding of various electric wire options, including their construction materials, insulation properties, and specific uses, to ensure that future projects meet both regulatory standards and consumer expectations.

As we delve into the top electric wire types to consider in the coming years, it is imperative to analyze the industry trends, technological advancements, and the regulatory landscape that will shape electrical installations in 2025. By doing so, we can better equip ourselves to make informed decisions for a safer and more sustainable electrical infrastructure.

Overview of Electric Wire Types for Modern Projects

When embarking on modern electrical projects, it's important to understand the different types of electric wires available and their specific applications. Among the most common are non-metallic sheathed cables (NM), which are widely used in residential wiring. These cables are suitable for indoor applications where protection against moisture is not as critical. Their flexible nature and ease of handling make them a preferred choice for DIY enthusiasts and professional electricians alike.

Another essential wire type to consider is the underground feeder (UF) cable, designed for direct burial underground. This type of wire is particularly useful for outdoor projects, such as connecting power to outdoor lighting or garden features. Additionally, it features a robust construction that prevents moisture intrusion and withstands various environmental conditions. For specialized applications, such as high-current situations, wires like THHN (Thermoplastic High Heat Resistant Nylon-coated) are often employed due to their heat and chemical resistance, making them suitable for industrial settings.

Understanding these wire types can enhance the efficiency and safety of your next electrical project, ensuring that the appropriate materials are matched to the specific requirements of the task at hand. As projects become increasingly technology-driven, staying informed about wire specifications, sizes, and installation requirements will enable you to meet the challenges presented by modern electrical systems.

Top Electric Wire Types to Consider for Your Next Project in 2025

| Wire Type | Applications | Gauge Range | Insulation Type |

|---|---|---|---|

| THHN/THWN-2 | General building wiring | 14 to 2 AWG | PVC |

| NM Cable | Residential wiring | 14 to 2 AWG | Non-metallic |

| MC Cable | Commercial and industrial use | 14 to 10 AWG | Metal clad |

| UF Cable | Underground projects | 14 to 6 AWG | Thermoplastic |

| Flexible Cord | Power tools and appliances | 16 to 6 AWG | Rubber or PVC |

| SPE Cable | Solar power installations | 10 to 4 AWG | Cross-linked polyethylene (XLPE) |

Key Factors to Consider When Choosing Electric Wire

When selecting electric wire for your upcoming projects in 2025, several key factors come into play to ensure safety, efficiency, and compliance with standards. One critical factor is the wire's gauge, which determines its capacity to handle electrical loads. According to the National Electrical Code (NEC), using the correct gauge is essential as it affects both performance and safety. For example, a 14-gauge wire is commonly used for lighting circuits, while a 12-gauge wire is suitable for outlets and larger appliances. Choosing the right gauge helps prevent overheating and reduces the risk of electrical failures, which could lead to costly repairs or hazards.

Moreover, insulation type is another paramount consideration. Different applications require specific insulation materials that can withstand environmental factors such as moisture, heat, and chemical exposure. The American National Standards Institute (ANSI) cites that thermoplastic insulation types like PVC and THHN are popular for their durability and resistance. According to a 2022 industry report by IBISWorld, the demand for high-quality insulated wires has surged, with an annual growth rate of approximately 6.4% driven by increased construction activities and electrical infrastructure developments. Additionally, understanding the voltage rating of the wire is vital, as using a wire rated for a lower voltage than your application's needs can pose serious safety risks and operational failures.

Top Electric Wire Types to Consider for Your Next Project in 2025

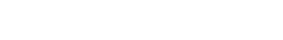

Popular Electric Wire Materials and Their Applications

When selecting the right electric wire for your project in 2025, it's essential to understand the various materials available and their specific applications. Copper wire remains a popular choice due to its excellent conductivity and flexibility. It is commonly used in residential and commercial wiring, making it ideal for applications that require reliable performance over time. Additionally, copper's resistance to corrosion ensures durability, particularly in environments where moisture is a concern.

Aluminum wire, on the other hand, is gaining traction for its lightweight properties and cost-effectiveness. Often used in overhead power transmission and long-distance wiring, aluminum's lower weight reduces installation costs and makes handling easier. However, it's vital to consider the appropriate connectors and methods for joining aluminum wire to mitigate issues related to oxidation, which can impact its conductivity.

For specialized applications, materials like thermoplastic or rubber-coated wires provide added insulation and protection against environmental factors. These wires are often used in outdoor installations or areas exposed to harsh conditions. Understanding the material properties and their suitability for different applications is crucial in ensuring safe and efficient wiring solutions for your upcoming projects.

Future Trends in Electric Wire Technology for 2025

As we look ahead to 2025, the landscape of electric wire technology is set to undergo significant transformation driven by advancements in materials science and energy efficiency requirements. According to a recent report by the International Wire and Cable Manufacturers Association, the market for advanced electric wires is expected to grow by approximately 10% annually, reflecting increased demand for smarter, more resilient wiring solutions. This growth is fueled by the widespread adoption of renewable energy sources and the need for wiring systems that can handle higher voltages and more complex energy management systems.

One of the emerging trends is the integration of smart technologies into electric wiring. These innovations include the development of wires with built-in sensors that can monitor energy flow and detect potential faults in real-time. The market research firm MarketsandMarkets highlights that by 2025, the smart wire technology segment could capture a market share of over $1 billion, enabled by the push for Internet of Things (IoT) applications in Energy Management Systems (EMS). Additionally, enhancements in insulation materials, such as cross-linked polyethylene (XLPE), provide improved thermal stability and resistance to environmental stressors, which is critical for the longevity and reliability of electrical installations.

Furthermore, sustainability will play a pivotal role in shaping electric wire technology. With stricter regulations on environmental impact, manufacturers are investing in eco-friendly materials and production processes. According to a study from the Global Ecological Wire Consortium, incorporating recycled materials into the manufacturing of electric wires can reduce carbon footprints by up to 30%. As the industry pivots towards more sustainable practices, the reliance on bioplastics and other green materials is expected to become a standard part of wire production, ensuring that future projects align with environmental goals while maintaining performance standards.

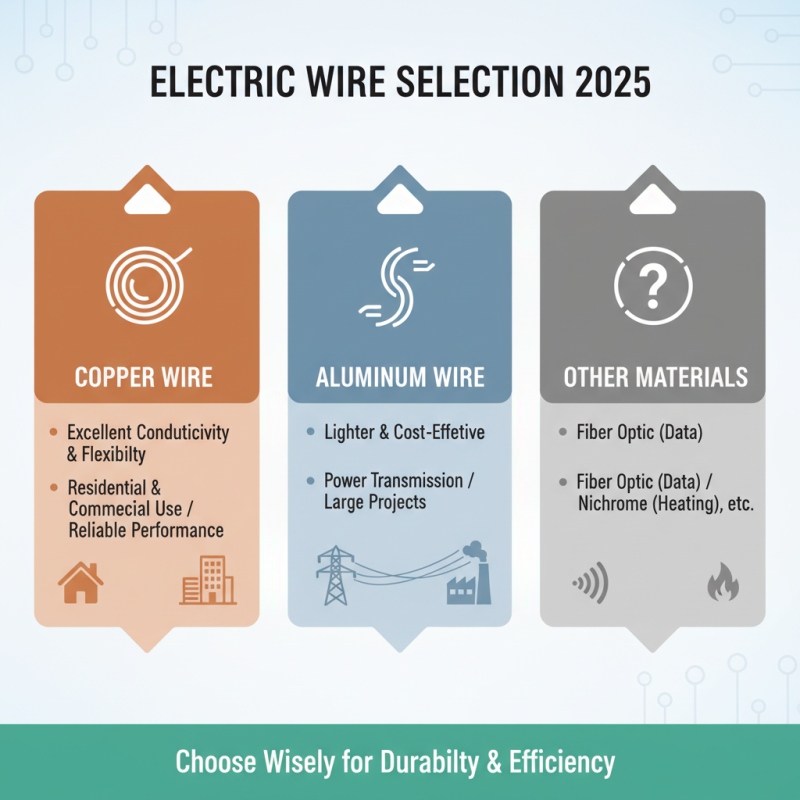

Safety Standards and Regulations for Electric Wires in Projects

When planning any electrical project in 2025, understanding the safety standards and regulations governing electric wires is crucial. The National Electrical Code (NEC) and Underwriters Laboratories (UL) Standards are two primary references that outline essential safety measures. According to the National Fire Protection Association (NFPA), adherence to these codes helps in significantly reducing the risk of electrical fires, which are responsible for approximately 20% of reported fire incidents in the U.S. each year. By choosing electric wires that meet these safety standards, project managers can ensure compliance, minimize liability, and enhance the safety of individuals interacting with the electrical systems.

In addition to the codes, regional regulations also play an increasingly important role in determining the specifications for electric wire installations. For instance, different states may have additional requirements concerning insulation types and environmental resistance based on local conditions. A report from the International Electrotechnical Commission (IEC) indicates that the demand for wires that can withstand extreme temperatures and moisture is on the rise, reflecting a shift toward sustainability and safety in electrical installations. Projects that prioritize compliance with both national and local regulations not only protect their investment but also contribute to an overall safer environment and promote community well-being in 2025.

Related Posts

-

10 Essential Tips for Choosing the Best Cable Hider for Your Home

-

Understanding the Basics of Cable and Wire Types for Everyday Applications

-

10 Essential Tips for Choosing the Best Cable Holder to Organize Your Space

-

What is Cable Management Systems? Benefits and Best Practices Explained

-

Top 10 Tips for Choosing the Right Electric Wire for Your Next Project

-

Understanding the Importance of Duct Cable in Modern Communication Systems