10 Essential Tips for Choosing the Right Electric Cable Duct Systems

In the evolving world of electrical infrastructure, selecting the right electric cable duct systems is crucial for ensuring safety, efficiency, and longevity. According to industry expert Dr. Emily Carter, a leading specialist in electrical engineering, "The effectiveness of an electrical system is significantly influenced by the choice of cable duct systems, which not only protect cables but also facilitate maintenance and upgrades."

When considering the myriad options available, it's essential to understand the fundamental characteristics that differentiate these systems. From materials and design to compliance with safety standards, the right choice can prevent hazards and minimize downtime in both residential and commercial applications. As the demand for reliable electrical solutions continues to rise, so does the need for well-informed decisions regarding electric cable duct systems.

This guide provides ten essential tips to assist in navigating the complexities of selecting the most suitable systems for your needs. By integrating expert insights and practical considerations, we aim to empower professionals and homeowners alike in making informed decisions that enhance the safety and functionality of their electrical installations.

Understanding Electric Cable Duct Systems: A Comprehensive Overview

Electric cable duct systems are crucial components in the effective management of electrical installations, offering protection and organization for wiring systems. These ducts provide a tailored infrastructure that safeguards cables from environmental elements and potential hazards, while also promoting ease of access for maintenance. Understanding the various types of electric cable ducts, such as floor ducts, wall ducts, and surface-mounted ducts, is essential for selecting the right system for any project.

When choosing an electric cable duct system, consider the size and type of cables you will be using. Ensuring that the duct can accommodate both current and future cabling needs is important for scalability. Additionally, pay attention to the material of the duct; materials like PVC and metal offer different benefits in terms of durability and protection. It’s worth mentioning that proper installation techniques can greatly enhance the functionality and longevity of the duct system.

Lastly, always think about the installation environment. Factors such as humidity, exposure to chemicals, and temperature fluctuations can influence the type of duct best suited for your needs. Make sure to choose a system that not only fits your immediate requirements but is also flexible enough to adapt to future changes in your electrical infrastructure. By keeping these tips in mind, you can ensure that your electric cable duct systems effectively support your electrical configurations while maintaining safety and efficiency.

Key Factors in Selecting Correct Electric Cable Duct Materials

When selecting the right electric cable duct materials, several key factors should be considered to ensure both effectiveness and durability. First and foremost, material composition plays a crucial role. Common options include PVC, steel, and aluminum, each with distinct characteristics. PVC is lightweight and resistant to corrosion, making it suitable for indoor applications, while steel offers high strength and robustness for outdoor environments. Aluminum, on the other hand, combines lightweight benefits with resistance to corrosion, making it suitable for various applications.

Another essential consideration is the duct's environmental resistance. Depending on the installation location, factors such as temperature fluctuations, humidity, and exposure to chemicals can impact the longevity of the duct system. Selecting materials that withstand these environmental challenges effectively ensures that the ducting system remains functional over time. Additionally, the fire resistance of the materials is paramount, particularly in commercial and industrial settings where safety is a top priority. By carefully evaluating these factors and understanding the specific requirements of the installation, one can choose a cable duct system that meets both performance and safety standards.

Analyzing Cable Duct Size and Capacity Requirements for Efficiency

When selecting an electric cable duct system, one of the most critical considerations is analyzing cable duct size and capacity requirements. The size of the duct directly influences the overall efficiency of the cable management system. A properly sized duct prevents overheating and ensures the smooth operation of electrical systems, as the right dimensions allow for adequate airflow around the cables. It is essential to calculate the number of cables and their respective dimensions accurately to avoid congestion within the duct. Overcrowded ducts can lead to electromagnetic interference and potential cable damage, disrupting not only performance but also safety.

Furthermore, understanding capacity requirements goes hand in hand with efficient design and future-proofing your installation. Assessing current and future cable loads, as well as variations in cable types—such as different jacket materials or insulation thicknesses—can help in determining the ideal duct specifications. By analyzing these factors, you can select a cable duct system that not only meets your current needs but also accommodates any expansions or modifications required in the future. Proper planning in duct size and capacity will ultimately enhance performance, reduce maintenance costs, and prolong the lifespan of your electrical systems.

Electric Cable Duct Systems: Size and Capacity Analysis

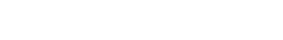

Importance of Environmental Conditions on Cable Duct System Performance

When selecting electric cable duct systems, environmental conditions play a critical role in their performance and longevity. Temperature fluctuations, humidity levels, and exposure to pollutants can significantly affect the integrity and efficiency of these installations. According to a report by the International Electrotechnical Commission (IEC), improper environmental assessment can lead to cable failures, affecting the overall reliability of power distribution systems. For instance, duct systems exposed to extreme temperatures are prone to thermal degradation, while high humidity can encourage corrosion of conductive materials.

Furthermore, the geographical location of the installation site must also be considered. In urban environments, increased levels of pollution can contribute to the accelerated wear of cable duct materials, necessitating the use of corrosion-resistant options. A study by the Institute of Electrical and Electronics Engineers (IEEE) highlights that cable systems in coastal areas experience significantly increased maintenance costs due to saltwater exposure, leading to higher operational expenses. Thus, conducting a thorough environmental impact assessment prior to the selection of cable duct systems is crucial to ensure optimal performance and minimize lifecycle costs.

Safety Standards and Regulations for Electric Cable Duct Installations

When selecting electric cable duct systems, adhering to safety standards and regulations is paramount. These standards serve as a framework to ensure installations are carried out safely and effectively, minimizing risks associated with electrical hazards, fire, and damage to the infrastructure. Compliance with national and local regulations, such as those outlined in the National Electrical Code (NEC) or relevant industry guidelines, helps in determining the appropriate materials, installation practices, and maintenance procedures necessary for safe electric cable management.

Furthermore, understanding the specific requirements for cable duct installations is essential for both new projects and upgrades to existing systems. This includes considering factors such as environmental conditions, load capacity, and accessibility for maintenance. It's crucial to consult with qualified professionals who are familiar with the latest safety regulations and industry best practices to ensure that the chosen duct systems not only meet operational needs but also enhance overall safety for users and maintenance personnel. Proper documentation and adherence to these regulations during the planning and installation phases can prevent costly mistakes and ensure long-term reliability of the electric cable duct systems.

10 Essential Tips for Choosing the Right Electric Cable Duct Systems - Safety Standards and Regulations for Electric Cable Duct Installations

| Tip No. | Tip Description | Safety Standard Reference | Regulation Compliance |

|---|---|---|---|

| 1 | Choose duct systems that are UV resistant for outdoor installations. | IEC 60529 | Meets IP65 standards |

| 2 | Select ducts with effective fire resistance ratings. | BS EN 13501-1 | Classified as B-s1, d0 |

| 3 | Ensure compatibility with cable sizes and types. | IEC 60364 | Compliant with Part 5-52 |

| 4 | Prioritize systems with good mechanical impact resistance. | EN 50262 | IK rating of at least IK08 |

| 5 | Check for systems that allow adequate ventilation. | BS 7671 | Part 4 Compliance |

| 6 | Use non-corrosive materials in harsh environments. | ASTM D5948 | Pass Corrosion Testing |

| 7 | Consider the installation ease and ergonomic design. | ISO 9241 | Based on ergonomic principles |

| 8 | Verify the long-term performance and warranty conditions. | ISO 9001 | Certified Quality Management |

| 9 | Ensure compliance with local electrical codes. | Local Electrical Code | Refer to specific jurisdiction |

| 10 | Consult with professionals for specific applications and needs. | N/A | Recommended Practice |

Related Posts

-

What is Cable Management Systems? Benefits and Best Practices Explained

-

10 Essential Tips for Choosing the Best Cable Holder to Organize Your Space

-

Top Electric Wire Types to Consider for Your Next Project in 2025

-

Mastering Wire Management Techniques to Enhance Workplace Productivity and Safety in 2024

-

Exploring the Essential Benefits of Cable Ducts in Modern Infrastructure Design

-

2025 Guide: How to Choose the Best Wire Duct for Your Cable Management Needs