How to Choose the Right Cable Wire for Your Electrical Projects?

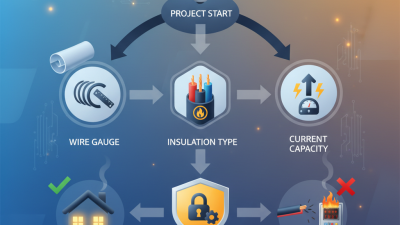

Choosing the right cable wire for any electrical project can be daunting. Experts like John Mitchell, a veteran in the cable wire industry, emphasize, "Selecting the correct cable wire is crucial for both safety and performance." Every project requires specific cable types, depending on the voltage and current needs.

Understanding the requirements helps in making informed decisions. For instance, using the wrong gauge can lead to overheating or even electrical fires. Many overlook the importance of this choice. A first-time DIYer may struggle with understanding specifications. It's essential to know the basics, but sometimes, we think we understand when we do not.

Reflecting on experiences can guide future choices. Missteps in wire selection often lead to costly mistakes. Cable wire selection impacts not just functionality, but safety too. Prioritize learning the fundamentals before starting a project. The right cable wire is not just a detail; it’s a foundational element of any electrical endeavor.

Understanding the Different Types of Electrical Cable Wires

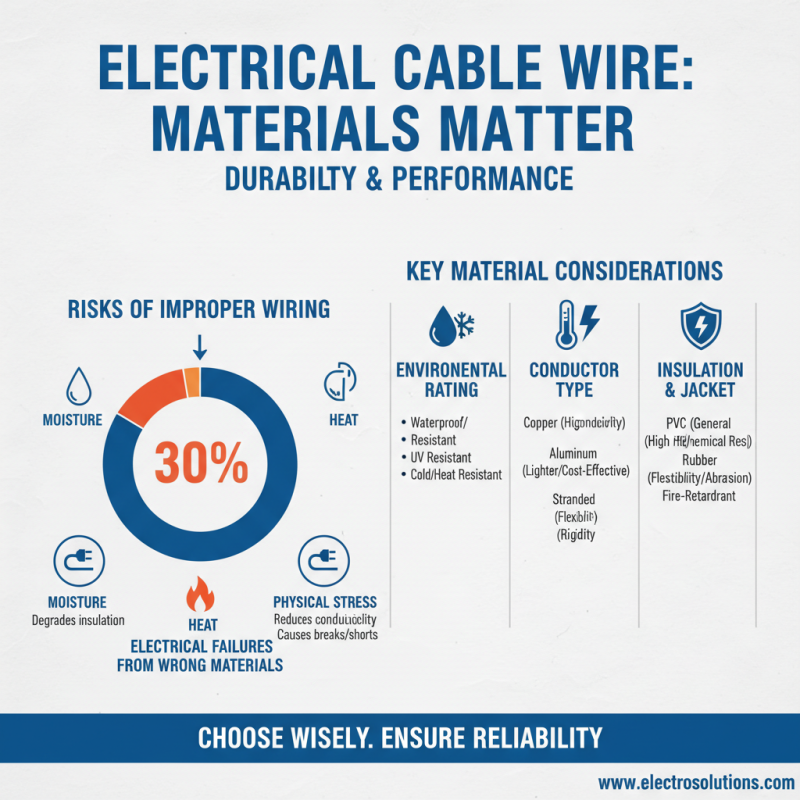

When choosing the right cable wire for your electrical projects, understanding the various types is crucial. For instance, the National Electrical Manufacturers Association (NEMA) states that copper wires are preferred for their conductivity. These wires can carry more current and are more durable than aluminum alternatives, which are cheaper but less efficient.

There are also differences in insulation types. PVC insulation is common due to its cost-effectiveness, but not all projects are suited for it. For higher temperatures, THHN (Thermoplastic High Heat-resistant Nylon-coated) wires may be needed. According to the Institute of Electrical and Electronics Engineers (IEEE), improper insulation can lead to failures in 30% of electrical installations. Awareness of temperature ratings is vital.

Another aspect is the gauge size. Thicker wires can handle more current but can be cumbersome to work with. A 12-gauge wire is standard for many residential applications, while 14-gauge is often lighter and easier to manage. However, using the wrong gauge can create hazards. Inconsistent wire choices lead to safety risks. Understanding these variations is an ongoing learning process for electricians and DIY enthusiasts alike.

How to Choose the Right Cable Wire for Your Electrical Projects?

| Type of Cable | AWG Size | Wire Material | Maximum Voltage | Applications |

|---|---|---|---|---|

| Copper NM-B | 14 | Copper | 600V | Residential wiring |

| PVC Insulated | 12 | Copper | 600V | General purpose wiring |

| THHN | 10 | Copper | 600V | Commercial and industrial use |

| Multi-conductor | 16 | Copper | 300V | Control systems and appliances |

| MC Cable | 12 | Copper | 600V | Power distribution |

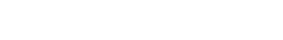

Assessing Electrical Current Requirements for Your Projects

When embarking on electrical projects, understanding the current requirements is crucial. Each project has different needs, and knowing how much current will flow through your cables is key. This impacts both safety and functionality. Consider the devices you will connect. Are they high-powered? A typical household appliance may draw a significant amount of current.

Tips: Always check the amperage of your devices. This will guide you in selecting the correct wire gauge. If you underestimate, you risk overheating.

Different materials can handle different amounts of current. Copper is often preferred due to its excellent conductivity. However, aluminum is lighter and cheaper. If you choose aluminum, make sure it’s rated for the same amperage as copper.

Tips: Refer to wire gauge charts for safe current limits. If the wire is too thin for the current, it could lead to failure or fire.

Be mindful of the length of your cable run as well. Longer runs may require thicker wire to minimize voltage drop. This might not seem significant at first, but over time it can affect your project's performance. Regularly testing your setup is also beneficial. If you're unsure, consult with experts or seek advice online.

Evaluating Environmental Conditions and Installation Locations

When evaluating environmental conditions and installation locations for cable wires, multiple factors come into play. Temperature extremes can greatly affect wire performance. For instance, wires rated for low temperatures may struggle in heating applications, leading to failures. According to the National Electrical Manufacturers Association, cables can degrade when exposed to consistent temperatures beyond their ratings.

Moisture and humidity are crucial aspects to consider as well. Cables in damp environments require better insulation to prevent corrosion. The Institute of Electrical and Electronics Engineers suggests that cables exposed to moisture should have a proper waterproof rating. This could mean the difference between a safe installation and hazardous failures.

Additionally, installation locations can pose unique challenges. Outdoor settings often present UV exposure risks. Indoors, the risk of interference from nearby electrical devices can occur. It’s essential to select cables that can withstand those specific risks. The data from various industry reports highlights that improper wire selection based on environmental conditions leads to up to 30% of installation failures. Understanding these details is vital. It allows for informed decisions, ensuring reliability and safety in electrical projects.

Identifying Safety Standards and Regulations for Cable Selection

When selecting cable wires for electrical projects, understanding safety standards and regulations is crucial. The National Electrical Code (NEC) outlines essential guidelines. Compliance with these regulations minimizes risks of fire and electrical hazards. In the U.S., neglecting these codes resulted in over 47,000 reported electrical fires in 2019 alone, according to the National Fire Protection Association (NFPA). Choosing cables that meet or exceed these standards can play a significant role in improving safety outcomes.

Local regulations may vary, impacting your selection of wire materials and insulation types. For instance, some regions mandate the use of specific insulation ratings, especially in residential settings. Many professionals recommend using thermoplastic or thermoset compounds, which enhance durability and heat resistance. However, there can be instances of misuse. Some projects may utilize lower-grade cables to cut costs, potentially leading to serious safety violations. A report from the Institute of Electrical and Electronics Engineers (IEEE) highlights that improperly installed wiring contributes to nearly 25% of electrical system failures.

Awareness of harmonization efforts among different countries can also help. International standards exist, yet communication failures often arise. Such discrepancies may lead contractors to overlook critical compliance details. Understanding these standards can reduce not only financial risks but also enhance overall project reliability. Missing the mark on safety regulations often stems from a disregard for professional advice or oversight during installation, leading to a need for ongoing education in the industry.

Electrical Cable Types and Their Usage in Projects

This chart represents various types of electrical cables and their common applications based on industry standards. Understanding the usage will help you choose the right cable for your electrical projects.

Choosing the Right Materials for Durability and Performance

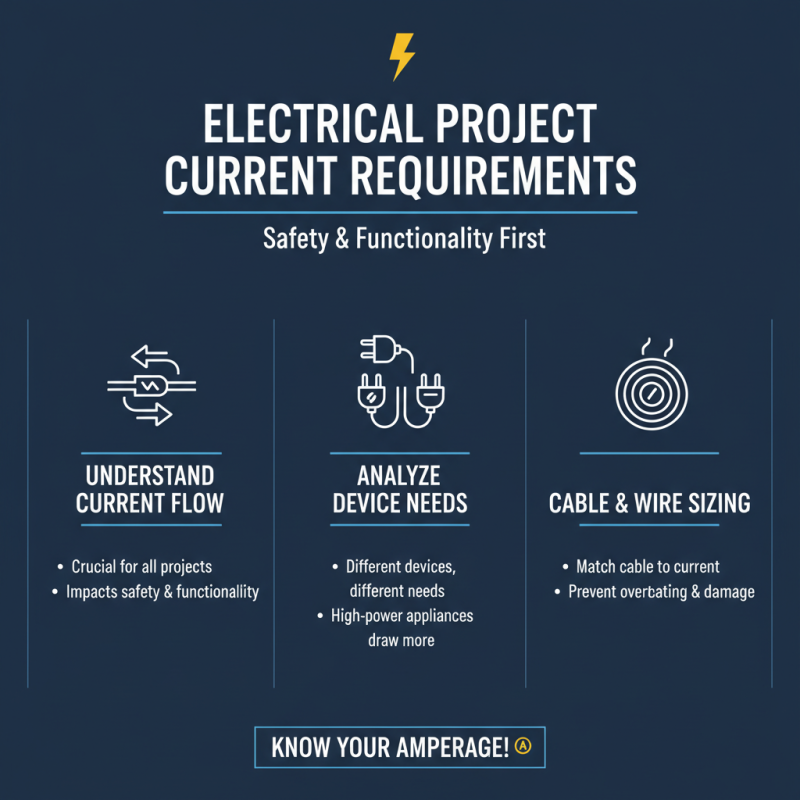

Choosing the right materials for electrical cable wire is crucial for durability and performance. According to industry reports, nearly 30% of electrical failures stem from improper wiring. Moisture, heat, and physical stress can all degrade cable performance. Using materials rated for specific environments helps minimize these risks.

Copper and aluminum are common choices for wire. Copper offers excellent conductivity and flexibility. However, it’s more expensive than aluminum. Aluminum, while lighter and cheaper, requires careful installation to prevent overheating. Reports show that 35% of electrical issues come from poorly installed aluminum wires. This highlights the need for precision during installation.

Environmental factors also play a role. For outdoor projects, UV-resistant materials are essential. Indoor use requires coatings for chemical resistance. A study indicated that 25% of cable failures result from exposure to corrosive elements. Always consider the installation site. Selecting materials without proper assessment can lead to long-term issues. Reflecting on these details can help achieve optimal results.

Related Posts

-

Understanding the Basics of Cable and Wire Types for Everyday Applications

-

What is Electric Wire and Why You Need to Choose the Right Type for Your Projects

-

How to Choose the Right Electric Wire for Your Project?

-

2026 Top Electric Cable Types You Need to Know?

-

Maximizing Electrical Safety: The Essential Role of Cable Ducts in Modern Infrastructure

-

10 Best Cable Cover Solutions for a Tidy Home or Office?