How to Choose the Right Electric Wire for Your Project?

Choosing the right electric wire for a project is crucial for safety and efficiency. According to the National Electrical Manufacturers Association, improper wire selection leads to 30% of electrical failures in homes. This statistic highlights the importance of understanding various wire types. Expert John Smith, a veteran in the electrical industry, states, “Choosing the right electric wire is not merely a technical decision; it’s a safety imperative.”

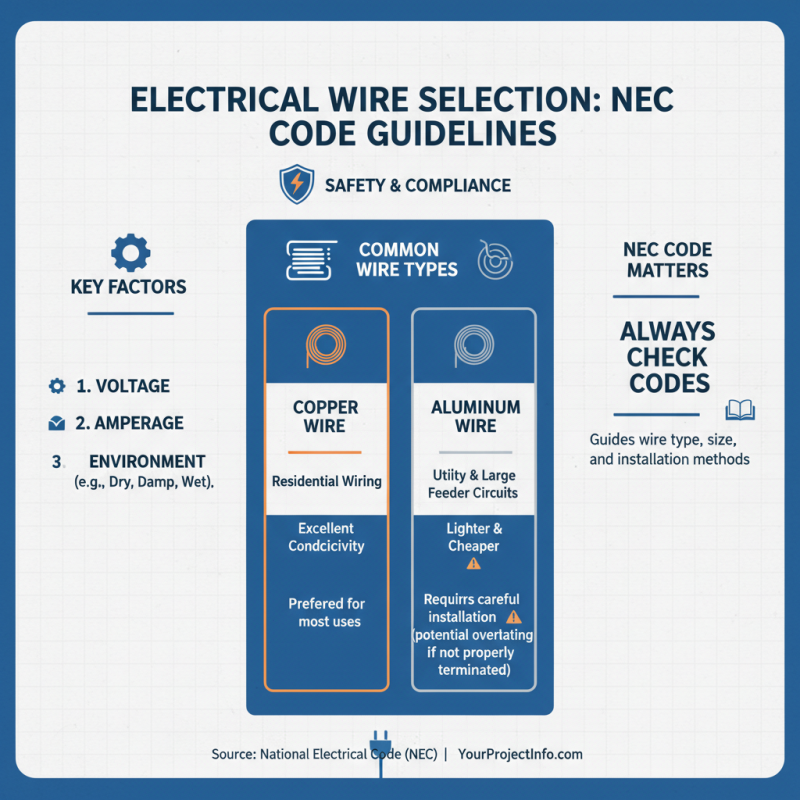

Selecting electric wire involves assessing several factors. Wire gauge, insulation type, and current capacity impact performance. For instance, using a wire with a lower gauge than required can cause overheating, posing fire risks. Many overlook these details, leading to costly mistakes. In an industry where regulations are strict, a misstep can have severe consequences.

Wire installation should reflect thoughtful decision-making. Ignoring specifications or guidelines can result in dangerous conditions. The process demands careful consideration and sometimes consultation with professionals. It’s essential to acknowledge that perfection in planning does not always guarantee flawless execution. Ultimately, making informed choices ensures better safety and functionality in any electrical project.

Understanding Wire Gauge: The Importance of AWG Standards in Projects

Choosing the right wire gauge for a project can be crucial. The American Wire Gauge (AWG) system helps standardize wire sizes. It ranges from 0000 (4/0) to 40. A lower number indicates a thicker wire, which can carry more current safely. For instance, 10 AWG wire can handle up to 30 amps, while 20 AWG only manages around 3.5 amps.

When selecting wire, consider the project's power needs carefully. Overusing a thin gauge can lead to overheating. Data from the National Electrical Code (NEC) suggests that using the correct gauge reduces fire risks significantly. Many DIY projects fail to follow these standards. This can create hazards that are easily avoidable.

A common mistake is underestimating the importance of distance. Longer wire runs may require a thicker gauge to minimize voltage drop. The NEC recommends a drop of only 3% for efficiency. If a project involves high power appliances, using inadequate wire can lead to performance issues. These factors highlight the demand for careful calculation in wire selection.

Identifying Voltage and Current Requirements for Safe Wiring Selection

When selecting electric wire for your project, identifying voltage and current requirements is crucial. Voltage determines the amount of pressure that pushes electrons through the wire. Higher voltage means you need thicker wire to prevent overheating. Current is the flow of electric charge. More current requires a larger wire gauge to handle the load safely.

Consider the specific requirements of your project. If you're powering a simple lamp, the wire can be thinner. For larger appliances, thicker wire is necessary to avoid risks. It's easy to overlook these details, yet they can lead to dangerous outcomes. Always check the amperage and voltage ratings. Miscalculations can cause short circuits or fires.

Don't forget to consider the environment. Outdoor wiring needs insulation that can withstand moisture and temperature changes. Indoor projects have different requirements. It’s essential to choose the right type to prevent deterioration. Hands-on experience can help, but be cautious. Incorrect choices lead to unnecessary mistakes. Assess carefully, and ensure everything aligns with your project needs.

Evaluating Insulation Types: Choosing Between PVC, THHN, and More

When selecting electric wire for your project, insulation type is crucial. PVC is a common choice. It is flexible and resistant to moisture. This makes it suitable for many indoor applications. However, PVC may not perform well in extreme heat. This can lead to potential hazards.

THHN wire is another popular option. It offers excellent thermal resistance and can handle higher temperatures. This makes it ideal for commercial buildings. However, THHN is not as flexible as PVC. In tight spaces, it may be challenging to work with.

Consider your project environment carefully. If you need durability and flexibility, PVC can be a solid choice. For high-temperature areas, THHN might be better. Reflect on the specific demands of your application. The right insulation can make a difference in safety and performance. Balancing these factors is essential.

Insulation Types Comparison: PVC vs. THHN vs. XLPE

Assessing Environmental Factors: Indoor vs. Outdoor Wire Specifications

When selecting electric wire for your project, considering the environment is crucial. Indoor wires typically use different materials than outdoor wires. For instance, indoors, wires are often designed for dry environments. They may not withstand moisture or UV exposure. In contrast, outdoor wires are built with insulation that can resist water and sunlight. The National Electrical Code outlines these differences clearly.

A study by the National Institute of Standards and Technology reveals that improper wire selection can lead to energy loss of up to 30%. Many people overlook insulation types and temperature ratings. Outdoor wires, for example, must be rated for extreme temperatures. The extreme elements can quickly degrade substandard materials. This deterioration compromises performance and safety, leading to potential electrical hazards.

Considering factors like humidity and temperature is essential. A wire suitable for one climate may not work in another. This often leads to frustrating projects where wires fail prematurely. Feedback from industry professionals highlights the frequency of these mistakes. Awareness and education on selecting the right wire can mitigate these issues. Proper choices lead to safer, more efficient installations, making it vital to get it right the first time.

How to Choose the Right Electric Wire for Your Project? - Assessing Environmental Factors: Indoor vs. Outdoor Wire Specifications

| Wire Type | Environment | Temperature Range (°C) | Moisture Resistance | UV Resistance | Typical Applications |

|---|---|---|---|---|---|

| THHN | Indoor | -20 to 90 | Low | No | Residential wiring, control circuits |

| UF | Outdoor | -20 to 60 | Medium | No | Underground feeder circuits |

| NM | Indoor | -10 to 60 | None | No | General purpose indoor wiring |

| SE | Outdoor/Indoor | -20 to 90 | Low | Yes | Service entrance circuits |

| XLPE | Outdoor | -40 to 90 | High | Yes | Heavy-duty applications |

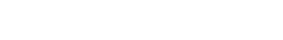

Applying NEC Code Guidelines to Ensure Compliance and Safety Standards

When selecting electric wire for your project, following NEC Code guidelines is crucial for safety and compliance. The National Electrical Code (NEC) provides a comprehensive set of standards. These guidelines specify the appropriate wire type based on factors such as voltage, amperage, and environment. For instance, copper wire is typically preferred for residential wiring due to its excellent conductivity. Aluminum wire is also used, but it requires careful installation to avoid overheating issues.

According to the National Fire Protection Association, improper wiring causes approximately 67,000 home fires each year, resulting in significant damages and safety risks. These statistics underscore the importance of adhering to NEC regulations, which help mitigate such hazards. Consider wire insulation types. For wet environments, use wires with ratings for moisture resistance. Always check the NEC tables for ampacity ratings. They provide essential guidance on the wire size needed for specific current loads.

It's essential to reflect on your project’s unique needs. Sometimes, it’s tempting to cut costs by opting for cheaper wire. However, this decision might lead to future problems. Always prioritize safety over savings. Installing the correct wire not only complies with NEC guidelines but also ensures long-term reliability. Neglecting these guidelines could lead to costly corrections and potential hazards.

Related Posts

-

Top 10 Tips for Choosing the Right Electric Wire for Your Next Project

-

Understanding the Basics of Cable and Wire Types for Everyday Applications

-

What is Electric Wire and Why You Need to Choose the Right Type for Your Projects

-

2025 Guide: How to Choose the Right Electric Wire for Your Projects

-

How to Choose the Right Custom Cable for Your Needs?

-

10 Essential Tips to Choose the Best Cable Supplier for Your Business Needs