How to Choose the Right Custom Cable for Your Needs?

Choosing the right custom cable is essential for achieving optimal performance in various applications. These cables are tailored to meet specific needs. They can be used in electronics, telecommunications, and more. The right custom cable ensures compatibility with your devices.

Many factors influence your choice. Consider the cable type, length, and materials. Different connectors can also impact efficiency and safety. A poorly chosen custom cable may lead to malfunctions or reduced performance. Assessing your requirements is crucial.

Take time to understand your needs. A gray area often exists between cost and quality. Cheaper options may not offer the durability you require. Balancing your budget while ensuring reliability can be tricky. Reflect on how your decision affects overall performance. Making the right choice in custom cable can lead to long-term benefits. Don't rush; evaluate all options carefully.

Understanding Your Specific Cable Requirements

Choosing the right custom cable requires a clear understanding of your specific needs. Start by considering the environment where the cable will be used. Will it be indoors, outdoors, or in a harsh environment? The cable’s material and insulation type play a crucial role here. For example, PVC might suffice for indoor use, but more durable materials like PUR or TPR are needed for outdoor applications.

Another important aspect is the cable length. Measure the distance accurately; too short means you’ll need extensions, while too long could lead to signal loss. Think about the cable's intended purpose. Will it transfer power, data, or both? Each use case requires different specifications.

Tips: Always check the cable’s rating. Know the amperage and voltage requirements. A common mistake is assuming one size fits all. Don't overlook the connectors as well. They should match your devices perfectly. Compatibility issues can waste time and money. If in doubt, it's wise to consult an expert. Reflect on how often you’ll need the cable. If it’s for daily use, investing in quality is worthwhile.

How to Choose the Right Custom Cable for Your Needs? - Understanding Your Specific Cable Requirements

| Cable Type | Material | Voltage Rating | Length | Application |

|---|---|---|---|---|

| Power Cable | Copper | 600V | 100 ft | Industrial Machinery |

| Coaxial Cable | Aluminum | 75 Ohm | 50 ft | Television & Radio |

| USB Cable | Copper | 5V | 6 ft | Data Transfer |

| Fiber Optic Cable | Glass | N/A | 150 ft | Internet & Networking |

| HDMI Cable | Copper | 19.2 Gbps | 10 ft | Audio/Video |

Identifying Different Types of Custom Cables Available

When selecting a custom cable, it’s essential to identify the various types available. Each type serves a distinct purpose. For instance, audio cables enhance sound quality. They come in many formats, such as XLR and TRS. If you seek crisp sound, these options may suit you well.

Data cables, on the other hand, focus on data transfer and speed. USB and Ethernet cables are common in this category. The choice depends on whether you need high speed or standard connectivity. Remember to consider connector types and length. A short cable might limit flexibility.

Power cables ensure efficient energy supply. Different voltages and amps are crucial here. Not every device uses the same specifications. A mismatch can harm your equipment. Evaluating your requirements is critical. Custom cables can greatly improve functionality but require thoughtful consideration.

Custom Cable Types and Their Popularity

This chart illustrates the popularity of different types of custom cables based on their usage in various industries. The data reflects the preferences of users from sectors such as telecommunications, audio/video, and industrial applications.

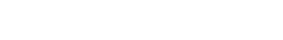

Evaluating Cable Specifications and Standards

When selecting a custom cable, understanding specifications is crucial. Cables differ significantly in performance based on various metrics. Key factors include gauge size, insulation type, and termination style. For instance, a cable's gauge indicates its current capacity. A thinner wire may not handle high power satisfactorily. Reports show that improper gauge selection can lead to performance issues in 30% of installations.

Insulation material is also essential. Some applications necessitate higher temperature ratings or chemical resistance. For example, PVC is common for general use, but it may not resist oil and chemicals well. An industry report indicated that 20% of cable failures stem from inappropriate insulation. This can lead to costly downtimes and repairs.

Lastly, adhering to industry standards is vital. Standards ensure safety and interoperability. The International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE) set critical guidelines. However, some manufacturers fail to meet these standards. A survey found that 15% of custom cables did not adhere to necessary specifications. Buyers should conduct thorough checks to avoid such pitfalls.

Considerations for Cable Length and Flexibility

When considering custom cables, cable length and flexibility are critical factors. A recent industry report highlighted that improper cable length can lead to signal loss. This loss often exceeds 2% for every meter exceeded. Therefore, measuring the installation space accurately is vital. Ensuring that cables are the right length minimizes unnecessary slack and maintains signal quality.

Flexibility plays a significant role in the performance of custom cables. A study indicated that cables designed for tight spaces or frequent movement can experience strain and potential failure. This could shorten their lifespan by 30%. Cables should be flexible enough to accommodate these conditions without compromising their integrity. However, striking a balance between durability and flexibility is challenging. Choosing materials that offer both can be difficult but is essential for prolonged use. Proper evaluation of environmental conditions will help in making the right choice. Some installations require high flexibility, while others may need sturdier options.

Determining Budget and Supplier Reliability Factors

When selecting a custom cable, budget plays a critical role. Consider what you can realistically spend. A high-quality cable can be an investment. However, an overly tight budget often leads to compromises in quality. A cheaper cable may damage your devices or underperform. Therefore, it’s essential to find the right balance between cost and reliability.

Supplier reliability is another crucial factor. Research potential suppliers thoroughly. Look for reviews or testimonials from other customers. Reach out to previous clients for their experiences. A supplier with a strong track record will often offer consistent quality. However, even established suppliers can sometimes deliver disappointing products. Keep an open mind and ask for samples before making a bulk order. This precaution can save you from significant losses in the long run.

In some cases, the urge to cut costs may lead to hasty decisions. Rushing could result in future problems, which may outweigh initial savings. It’s worth taking the time to evaluate both budget and supplier reliability. Recognizing this can help you make a more informed decision for your custom cable needs.

Related Posts

-

Mastering Wire Management Techniques to Enhance Workplace Productivity and Safety in 2024

-

Ultimate Guide to Innovative Cable Holder Solutions for a Clutter Free Space

-

10 Essential Tips for Choosing the Right Cable Supplier for Your Business Needs

-

2025 Top 5 Cable Conduits: The Best Solutions for Your Wiring Needs

-

Maximizing Electrical Safety: The Essential Role of Cable Ducts in Modern Infrastructure

-

2025 Top Trends in Cable Baskets: Essential Guide for Organizing Wires