2026 Best Wire Duct Solutions for Organized Electrical Wiring?

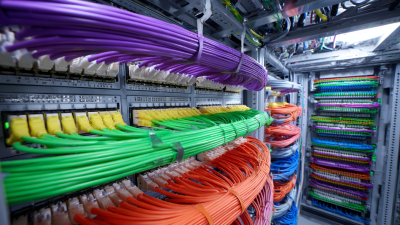

In the modern world, electrical systems must be efficient and organized. The key to achieving this is through the effective use of wire ducts. These solutions play a vital role in managing cables and improving safety. A well-structured wire duct system prevents clutter and reduces the risk of accidents.

Wire ducts come in various shapes and materials. Each option has its advantages, tailored for specific environments. Some may prefer plastic ducts for their lightweight characteristics, while others opt for metal due to its durability. Visualizing the setup can help identify the best solutions.

No system is perfect. Over time, wires can become tangled or damaged. This leads to the necessity for routine inspections and maintenance. Proper implementation of wire ducts helps mitigate these issues. In 2026, finding the ideal wire duct solutions will remain essential for keeping electrical wiring organized and safe.

The Importance of Wire Duct Solutions in Electrical Organization

Wire duct solutions play a critical role in maintaining organized electrical wiring. An estimated 30% of electrical failures stem from poor wiring management. This chaos can lead to costly downtime and unsafe working environments. Properly organized wiring minimizes the risk of errors and increases efficiency.

Adopting high-quality wire ducts can streamline cable management. Research indicates that businesses that invest in proper wiring systems often see a return on investment within two years. Effective wire management prevents tangling and overheating. It also improves accessibility for routine maintenance. This can save time and resources.

However, there is often a reluctance to prioritize wire duct systems. Some companies may overlook the long-term benefits due to upfront costs. This approach can backfire. Without effective organization, businesses face increased risks and potential fines. Emphasizing the value of wire ducts can change this perspective. Better wiring organization leads to safer, more productive workspaces.

2026 Best Wire Duct Solutions for Organized Electrical Wiring

| Wire Duct Type | Material | Dimensions (mm) | Suitable for | Color Options | Price Range ($) |

|---|---|---|---|---|---|

| Cable Duct | PVC | 20 x 10 | Residential & Commercial | Grey, White | 15 - 25 |

| Wire Tray | Metal | 300 x 70 | Industrial | Galvanized, Stainless Steel | 50 - 100 |

| Raceway | Aluminum | 25 x 16 | Commercial | Black, Anodized | 30 - 60 |

| Cable Management Box | Plastic | 15 x 15 | Home Office | White, Black | 20 - 40 |

| Underfloor Ducting | Concrete | Variable | Commercial Buildings | N/A | Depends on Installation |

Key Features of Effective Wire Duct Systems for 2026

In 2026, effective wire duct systems will play a crucial role in organized electrical wiring. A report by the Institute of Electrical and Electronics Engineers (IEEE) highlights that efficient wire containment can reduce installation times by up to 30%. This efficiency results from well-designed ducts that promote easy access and management of cables.

When evaluating wire duct solutions, certain features stand out. For instance, modular designs allow for flexibility in system configurations. The ability to adjust layouts easily is important. Additionally, materials that offer better heat resistance can enhance safety. A study from the National Fire Protection Association (NFPA) indicates that approximately 30% of electrical fires stem from poor wiring practices.

However, not all systems deliver effective performance. Many ducts on the market today lack adequate ventilation. This can lead to overheating, particularly in densely packed environments. Another common mistake is neglecting to consider future scalability. Many installations may work well now but could become problematic later. Keeping such aspects in mind will ensure better wire duct solutions in 2026.

Industry Standards and Compliance for Wire Duct Use

When it comes to wire duct solutions, compliance with industry standards is crucial. The National Electrical Manufacturers Association (NEMA) emphasizes that proper wire management reduces hazards and improves overall safety. Effective organization can prevent overheating and electrical shorts. Reports suggest that nearly 30% of electrical fires result from poor wiring practices.

Wire ducts must adhere to specific dimensions and ratings defined by organizations like the Underwriters Laboratories (UL). These standards ensure that wire ducts can handle various environmental challenges. For instance, wire ducts used in exposed areas must be UV-resistant and durable. Failing to meet these criteria can lead to significant risks.

While many installations meet basic requirements, a lack of ongoing evaluations can lead to issues. Regular inspections are necessary to ensure compliance. Data shows that facilities that conduct routine audits report a 25% reduction in wiring hazards. It's a clear reminder that adherence to standards is not a one-time effort but requires continuous attention and improvement.

Comparative Analysis of Materials Used in Wire Duct Manufacturing

When it comes to wire ducts, the choice of materials plays a crucial role. Plastic and metal are the dominant options, each with distinct properties. Plastic ducts often offer lightweight solutions and resistance to corrosion. Reports suggest that plastic wire ducts account for about 55% of market share. They are easy to install, but they can be less durable in high-temperature environments.

Metal wire ducts, particularly aluminum and steel, present a contrasting profile. These materials boast high strength and durability. In industrial settings, they are preferred for their robustness. However, metal ducts can be heavier and more expensive to install. Data indicates that metal duct solutions have a 35% market share. This reflects their popularity in places where safety and reliability are non-negotiable.

An ongoing challenge is finding a balance. Many industries prioritize cost-efficiency while ensuring durability. There's a risk in choosing lower-cost materials that could compromise safety. A recent survey revealed that 70% of professionals express concerns about the long-term reliability of budget options. As projects become more complex, the right material selection becomes more critical. Further market research could elucidate trends and preferences, leading to more informed decisions.

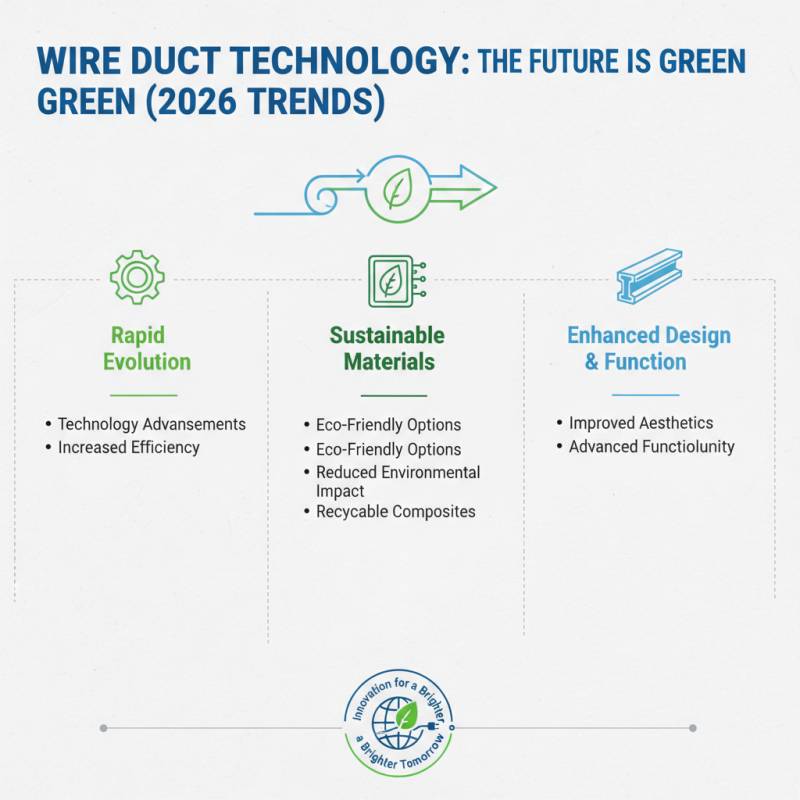

Future Trends in Wire Duct Technology and Design Innovations

As we look toward 2026, wire duct technology is evolving rapidly. Future trends indicate a shift towards more sustainable materials. Companies are increasingly focusing on eco-friendly options that reduce environmental impact. This innovation improves not only aesthetics but also functionality.

Smart wire ducts are on the rise. These systems will allow for real-time monitoring of electrical flow. This feature ensures safety and optimizes performance. Implementing such technology can greatly reduce energy waste. Think about the potential savings in energy bills here!

Tip: When organizing wiring, consider color-coded ducts. This simple change can make troubleshooting much easier later on.

As designs evolve, customization becomes essential. The ability to tailor wire duct sizes and shapes can enhance organization. Larger installations may require modular designs to adapt to varying needs. Yet, some may find it challenging to keep track of customizable options. It’s a delicate balance between flexibility and functionality. Ensuring clarity in design can help further simplify decision-making.

Tip: Regularly assess your installation for maintenance. This can prevent costly issues and extend the life of your wiring system.

Related Posts

-

Maximizing Electrical Safety: The Essential Role of Cable Ducts in Modern Infrastructure

-

Maximizing Efficiency: How Electric Cable Ducts Improve Cable Management and Reduce Risks in Modern Infrastructure

-

Mastering Wire Management Techniques to Enhance Workplace Productivity and Safety in 2024

-

2025 Guide: How to Choose the Best Wire Duct for Your Cable Management Needs

-

2025 Top 5 Cable Conduits: The Best Solutions for Your Wiring Needs

-

How to Improve Wire Management in Your Workspace?