2025 Guide: How to Choose the Right Electric Wire for Your Projects

Choosing the right electric wire for your projects is crucial for ensuring safety, efficiency, and functionality. With the growing demand for electric systems in various applications, from residential wiring to industrial setups, understanding the types, specifications, and applications of electric wire has become more important than ever. Whether you are a DIY enthusiast or a seasoned electrician, this comprehensive guide aims to equip you with the knowledge needed to make informed decisions regarding electric wires.

In the world of electrical installations, selecting the appropriate wire can significantly impact the performance and longevity of your projects. Factors such as wire gauge, insulation type, and voltage rating play critical roles in determining the suitability of electric wire for specific applications. Moreover, with the advancements in electrical technology and materials, it's essential to stay informed about the latest standards and best practices. This guide will help you navigate through the complexities of electric wire selection, ensuring that you achieve safe and reliable electrical systems in your endeavors.

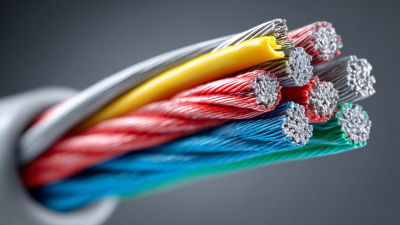

Understanding the Basics of Electric Wire Types and Ratings

When selecting the right electric wire for your projects, it's crucial to understand the various types and ratings available. Electric wires are typically categorized by their gauge, insulation type, and application, each of which plays a significant role in their performance and safety. According to the National Electrical Code (NEC), wire gauge, indicated by American Wire Gauge (AWG), determines the wire's capacity to carry electrical current. For example, a 12-gauge wire can handle up to 20 amps, making it suitable for general household circuits, whereas a 14-gauge wire is rated for 15 amps, primarily used for lighting circuits.

Furthermore, different insulation types such as THHN, NM, and UF provide varying degrees of protection based on the wire's intended environment. THHN wire, with its thermoplastic insulation, is ideal for dry indoor applications, rated for up to 90°C. Conversely, NM (non-metallic) cable is often employed in residential buildings, providing both electrical and physical protection from wear and tear. The choice of wire insulation and rating not only affects the efficiency of the electrical system but also contributes to overall safety. As per the latest report from the Institute of Electrical and Electronics Engineers (IEEE), improper wire selection is a leading cause of electrical fires, underlining the importance of adhering to industry standards and guidelines while making selections for electrical projects.

2025 Guide: How to Choose the Right Electric Wire for Your Projects

| Wire Type | Use Case | Wire Gauge | Current Rating (A) | Voltage Rating (V) |

|---|---|---|---|---|

| THHN | General Purpose Wiring | 12 AWG | 20 | 600 |

| NM-B | Residential Wiring | 14 AWG | 15 | 300 |

| UF | Underground Feeder | 12 AWG | 20 | 600 |

| MC | Metal-Clad Cable | 10 AWG | 30 | 600 |

| Romex | Interior Wiring | 12 AWG | 20 | 300 |

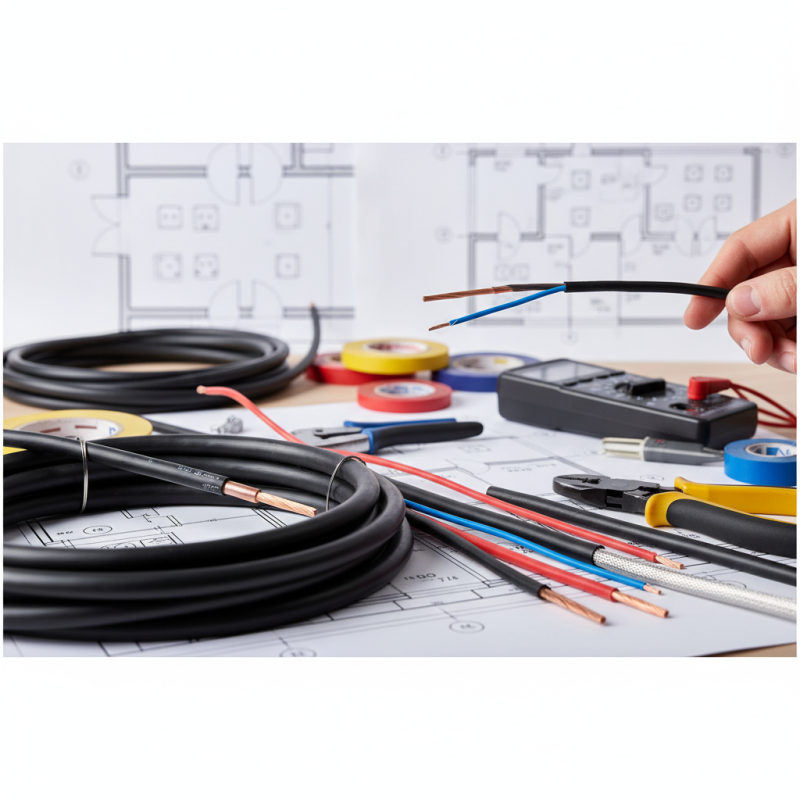

Assessing Voltage and Amperage Requirements for Your Project

When planning an electrical project, understanding the voltage and amperage requirements is crucial for selecting the right electric wire. Voltage, measured in volts, refers to the electrical potential difference, while amperage, measured in amps, indicates the amount of current flowing through the wire. It's important to match the wire's ratings to the specific needs of your project to ensure safety and efficiency.

Tips: Always consult the National Electric Code (NEC) guidelines for your region to determine the appropriate wire size based on the voltage and amperage requirements of your project. For instance, if you are working with a 120V circuit that draws 10 amps, a wire gauge of 14 AWG (American Wire Gauge) is typically suitable. However, higher amperage demands may require thicker wires to prevent overheating and potential hazards.

Another important factor to consider is the length of the wire run. Longer distances can lead to voltage drops, which can affect the performance of your devices. As a rule of thumb, if the wire run exceeds 100 feet, consider using a thicker gauge wire to compensate for this loss. Ensuring that your wire choice is adequate for both voltage and amperage will help maintain a safe electrical environment in your project.

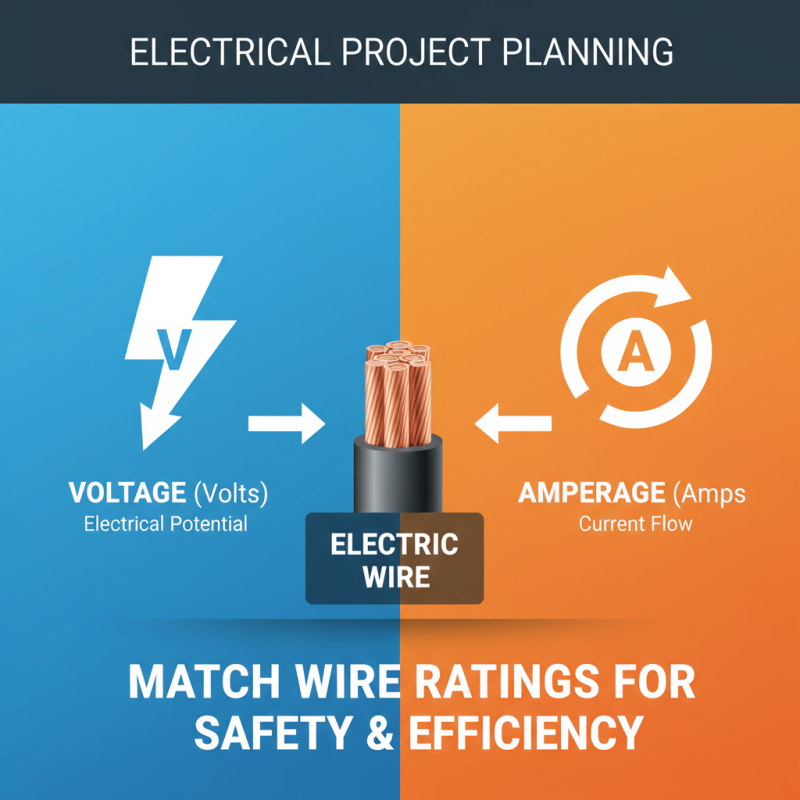

Identifying the Appropriate Insulation Material for Different Applications

When selecting the right electric wire for your projects, choosing the appropriate insulation material is critical to ensure safety and efficiency. Different applications require different types of insulation to withstand specific environmental conditions and electrical demands. According to a recent report by the International Electrotechnical Commission (IEC), insulation materials can significantly impact the reliability and lifespan of electrical installations. For instance, PVC (Polyvinyl Chloride) is commonly used in residential wiring due to its excellent flexibility and resistance to moisture, while XLPE (Cross-Linked Polyethylene) is preferred for higher temperature applications because of its superior thermal stability.

Moreover, more specialized insulation materials like Teflon (PTFE) are beneficial in high-frequency applications due to their low dielectric constant and high chemical resistance. The growing demand for energy-efficient solutions has led to an increase in the use of thermoplastic elastomers as they enhance performance in various temperature ranges while maintaining flexibility. Industry data indicates that projects incorporating advanced insulation technologies can reduce energy loss by up to 30%, highlighting the importance of selecting the correct insulation material for enhancing energy efficiency and minimizing operational costs.

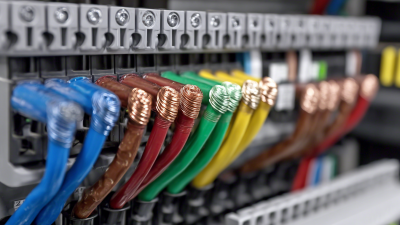

Determining Wire Gauge: Choosing the Right Thickness for Safety

When embarking on electrical projects, selecting the right wire gauge is a critical aspect that ensures both safety and performance. The wire gauge refers to the thickness of the conductor, which directly affects its current-carrying capacity. According to the National Electric Code (NEC), improper gauge selection can lead to overheating, fire hazards, and equipment damage. For instance, a wire that is too thin for the intended load can experience excessive resistance, leading to voltage drop and inefficiency. The NEC provides guidelines such as using 14-gauge wire for up to 15 amps and 12-gauge wire for up to 20 amps, thereby helping to mitigate these risks.

Data from the Occupational Safety and Health Administration (OSHA) illustrates that electrical failures contribute to a significant percentage of workplace injuries. By adhering to recommended wire gauge standards, professionals can significantly reduce the likelihood of accidents. Research conducted by the Electrical Safety Foundation International (ESFI) reveals that using appropriately sized wires can improve overall system reliability and decrease maintenance costs. As such, understanding the load requirements and following established gauge guidelines is essential for achieving safe and effective electrical installations.

2025 Guide: How to Choose the Right Electric Wire for Your Projects

This chart illustrates the recommended wire gauge (thickness) for different electrical applications, ensuring safety and efficiency in your projects. Use this guide to select the appropriate wire size based on the amperage requirements of your specific applications.

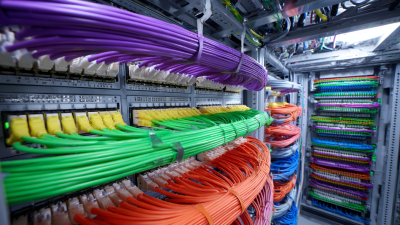

Analyzing Environmental Factors Affecting Wire Selection and Durability

When choosing electric wire for your projects, environmental factors play a crucial role in determining both the suitability and longevity of the materials used. One key aspect to consider is the climate where the wire will be installed. For instance, areas with high humidity, extreme temperatures, or significant temperature fluctuations can lead to accelerated wear and corrosion. Wires that are exposed to moisture may require insulation that is specifically designed for waterproof applications, while those in regions with extreme heat might need materials that can withstand elevated temperatures without degrading.

Additionally, the physical environment surrounding the installation site must be assessed. Consider factors such as exposure to UV radiation, potential chemical exposure from nearby plants or substances, and the risk of physical abrasion from soil movement or contact with other materials. Wires intended for outdoor use should be rated for UV resistance to prevent the insulation from breaking down over time. Similarly, locations near agricultural or industrial operations may necessitate wire with enhanced chemical resistance to ensure durability. By thoroughly evaluating these environmental elements, you can make informed decisions that enhance the performance and lifespan of the electric wire chosen for your projects.

Related Posts

-

How to Choose the Right Cable and Wire for Your Electrical Projects

-

Top 10 Tips for Choosing the Right Electric Wire for Your Next Project

-

What is Electric Wire and Why You Need to Choose the Right Type for Your Projects

-

10 Essential Tips for Choosing the Right Electric Wire: Industry Insights and Data

-

Maximizing Efficiency: How Electric Cable Ducts Improve Cable Management and Reduce Risks in Modern Infrastructure

-

2025 Guide: How to Choose the Best Wire Duct for Your Cable Management Needs